Hot air circulation drying oven adopts hot air circulation with high temperature resistant axial flow fan and automatic temperature control system. Most hot air is circled inside the oven, and the drying process in hot air drying machine is high heat efficiency and energy saving. Hot air circulating oven is suitable for pharmaceutical, chemical, foodstuff, and light industries. It can be used in heating and drying raw materials, Chinese traditional medicines, powders, granules, vegetables, etc.. Obviously, hot air drying oven is popular in the market. While in the international commercial drying oven market, there are countless manufacturers and suppliers. Here are some suggestions to help customers choose a suitable drying oven. Moreover, there are also some advisable tips for how to install and maintain the food dryer machine.

I. How to Choose The Suitable Drying Oven

1. The capacity of drying oven

Totally speaking, the greater the volume will bring stronger production capacity, and the cost will be higher. The factors influencing production capacity are as follows: electric power, characters of raw materials, production space and etc.. Generally, the capacity of drying oven can be calculated by the baking vehicles like a single door with single baking vehicle, double door with double or four baking vehicles, four doors with eight baking vehicles. One baking vehicle can hold ten drying trays, and one drying tray is with the size of 640*460*50mm. So you can work out the capacity of the drying oven, and choose the suitable one for you.

2. Characteristics of raw materials

The raw materials are the key factor to decide what kind of drying machine you can use. For powder materials, you should choose microwave dryer machine but not hot air circulation drying oven, because the powder would be discharged from the drying machine by the wind.

3. Structure of drying oven

The air blow methods consist of vertical ventilation and horizontal ventilation. You can choose the suitable structure based on the properties of raw materials.

4. Operating Temperature and Drying Temperature Range

When operating temperature is below 290℃, please choose the dryer machine with drying temperature range of RT+10~300℃. If the operating temperature is between 300℃ and 450℃, please choose the drying machine with a drying temperature of 500℃. For that of 450℃-560℃, the drying oven of 600℃ is OK.

II. How to Install the Drying Oven

1. It will be better to install a drying machine in the place of good ventilation, dry & clean conditions. A good working environment is a major factor to prolong the machine service life.

2. It is prohibited that there are volatile and extremely flammable materials in the drying oven in the case of an explosion.

3. Before starting the machine, please check the electric insulating property and make sure there are no creepage and short circuit in all the circuits.

4. After installation, please check whether all the screw and bots are secured.

III. Maintenance of the Drying Oven

1. After work, the surface of drying oven should be cleaned with a soft cloth to keep clean. The inner of drying oven also should be clean regularly to avoid corrosive material left, which can prolong the service life of drying oven.

2. The working temperature cannot be over the already existing temperature. During the operation, if there are some abnormal sound, please turn off the machine. After the high-temperature operation, you can not turn off the main switch immediately. Turn on the fan and let the heat out of the machine.

3. Check the drying oven regularly.

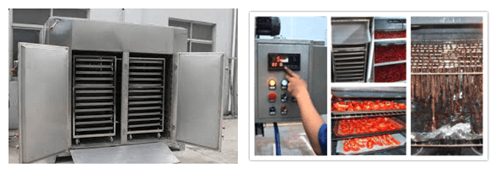

Our Machine is the expert in manufacturing drying ovens and we can provide high-quality dryers. There are three capacities of hot air dryer machines for choice based on your business demands: small single door hot air drying oven, double door hot air oven, and large hot air drying machine. We have good cooperation with many customers all over the world. Till now, our drying machines have been exported to more than 30 countries and regions.