Mesh Belt Industrial Chili Drying Equipment

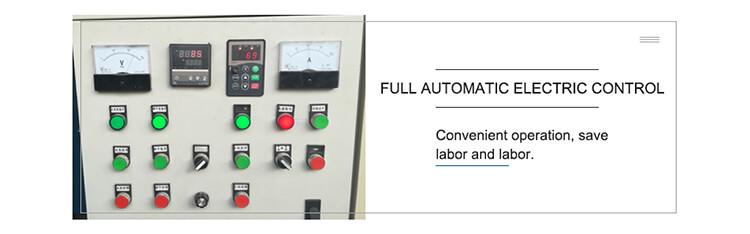

This continuous mesh belt industrial chili drying machine is the best choice drying machine for large scale chili drying production. It has the advantage of fast drying speed, high evaporation intensity and best product quality. The running speed, drying temperature and humidity can be adjusted to meet the different chili condition and drying requirement

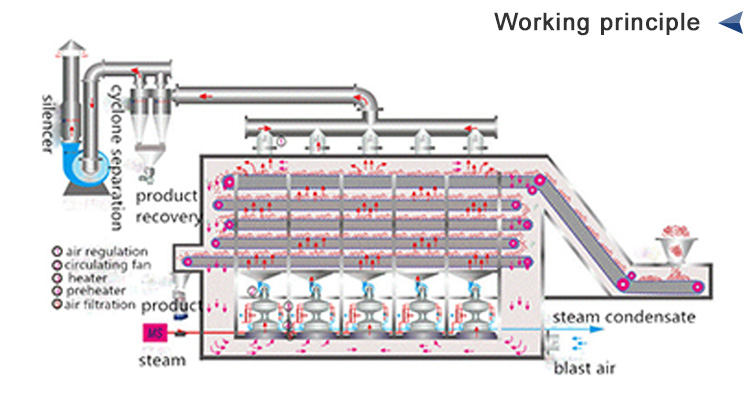

The working principle of continuous mesh belt chili drying machine:

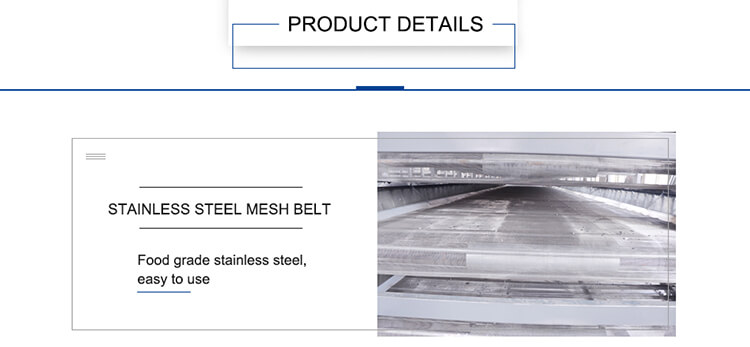

The continuous belt chili drying machine utilize the hot air produced by the heat furnace as the drying medium. Through the hot air distribution unit, the hot air is transported to the mesh belt to dry the chili. The Chili is spread evenly in the mesh belt and moved in the dryer layer by layer via the belt conveyor feeding system. With the help of exhaust fan, the hot air penetrates the wet chili on each layer of drying belt for heat transfer and take away the evaporated moisture, so as to achieve the purpose of chili drying. The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours. The equipment easy to operate, save time, drying process health and environment friendly.

The structure of chili drying equipment

1.Heat Exchange Furnace

2.Induced Draft Fan

3.Feeding Conveyor

4.Distribute Device

5.Dryer Body

6.Discharge Device

7.Electricicy Control Panel

Advantages of chili drying equipment:

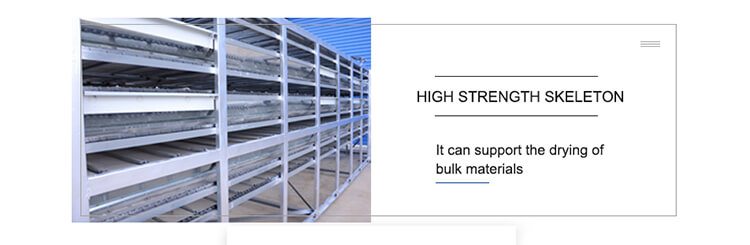

1.Adopt multilayered structure, large area of drying , it can continuous produce in large quantities.

2.Heat exchange furnace adopt new fireproofing and high quality steel, although the strict calculation of construction completion , easy construction and operation, easy maintenance.

3.The air blow to the material is pure,will not pollute the materials.

4.Bidiretional oven door, in order to facilitate inspection, dismantling parts, easy to open and clean.

5.The chili drying equipment doesn’t require a lot of civil works,small footprint,low installation costs.

Other Application of the Continuous Mesh Belt Drying Equipment

1 Fruit and Vegetable Drying

For dehydration and drying of all kinds of vegetables and fruits, such as: jujube, radish, onion, pepper, garlic, pumpkin, papaya, bamboo shoots etc.

2 Nut Flower and Herb Drying

Drying many kinds of roots, stems, leaves, flowers, nut kernels and herbal

3 Other Mertial

Such as rice, cereal, fungus, shrimp, sphagnum, pastures, roses, industrial peppers etc.

Mesh Belt Chili Drying Machine Type and Parameters

| Model(Width*Length) | DW1.5-6-4 | DW2-8-4 | DW2-9-4 | DW2-10-4 | DW2-12-4 | |

| Layers | 4 | 4 | 4 | 4 | 4 | |

| Drying area(㎡) | 29 | 45 | 51 | 57 | 69 | |

| Spread thickness of material(mm) |

50-200 |

|||||

| Working temperature(℃) |

0-120 |

|||||

| Drying time(hour) |

0.1-5 |

|||||

| Capacity(t/h) | 100-150kg/h | 200kg/h | 250kg/h | 300kg/h | 400kg/h | |

| heat exchange furnace(M) | 3.2*1*2.7 | 3.9*1.26*3 | 3.9*1.26*3 | 4.7*1.5*3 | 4.7*1.5*3 | |

| Induced draft fan(kw) | 11 | 15 | 15 | 22 | 22 | |

| Exhaust fan(kw) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | |

| Feeding conveyor(kw) | 1.5 | 2.2 | 2.2 | 2.2 | 3 | |

| Discharge conveyor(kw) |

0.55 |

|||||

| Total power(kw) | 14.55 | 19.25 | 19.95 | 26.95 | 27.75 | |

| LP gas consumption

(90 degree fanrenheit) |

20m³/H | 25m³/H | 28m³/H | 30m³/H | 36m³/h | |

| Place requirement

(W*L*H)M |

4.5*14*2.7 | 5*19*2.8 | 4.5*20*2.8 | 5.5*21*2.8 | 5.5*23*2.8 | |