Mesh Belt Hemp Drying Machine

Our mesh belt hemp drying machine is designed to utilize the combination of heat and air to rapidly dry hemp leaves and flowers. Material enters via the conveyor into a multi-layer belt system whereby it is dried by airflow and heat. The Mesh Hemp Belt Dryer is a fast, industrial-scale solution to massive hemp harvest drying. All material touchpoints are made from 304 stainless to meet food-grade standards.

Benefits of Our Mesh Belt Hemp Drying Machine

LOW OPERATING COST

The Belt hemp dryer utilizes a heat recapture system which recycles up to 80% of the system heat for maximum efficiency and operating cost savings.

FAST DRYING TIME

Approximate drying time 4-5 hrs from start to finish. Production is continuous so drying time starts when material enters the belt wet and exits dry.

MATERIAL REQUIREMENTS

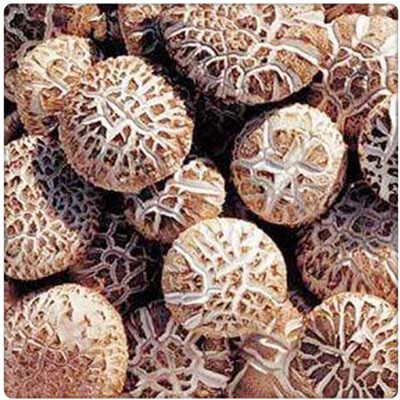

Hemp leaves, shredded flower, biomass

5/16″-1″ material diameter

Moisture Input 80%, Output 10-13%

Heating temperature 104-194F, 40-90C

The hemp drying machine working principle

Hemp flower and hemp leaf are transported by the feeding conveyor to the inside of the dryer. The material passes layer by layer via the conveyor belt, while, the hot air passes through the material from the bottom to top. The dried Hemp flower and hemp leaf are conveyed by the discharge conveyor. The final moisture comes out of the top of the dryer.

The Structure of Mesh Belt Hemp Drying Machine

1.Heat Exchange Furnace

2.Induced Draft Fan

3.Feeding Conveyor

4.Distribute Device

5.Dryer Body

6.Discharge Device

7.Electricicy Control Panel

If you are a hemp processing company or you’re a farmer with 1000 acres or more, please consider the mesh belt hemp drying machine. The Mesh Hemp Belt Dryer is a fast, industrial-scale solution to massive hemp harvest drying

If your hemp drying capacity requirement is not very large, you may want to consider heat pump drying machine. The temperature never goes above 80 degrees to be sure we don’t smash the trichomes that contain volatile terpenes or cannabinoids

Maximum Your Hemp Production ROI

Hemp is in high demand and can be used in a variety of products. Hemp Drying is an essential part of processing hemp for further extraction, but the process can take a significant amount of time and effort. Hemp biomass often has a high moisture content, even up to 85%, which has to be reduced to an acceptable level in order to extract quality final product. Manual drying isn’t feasible for all hemp producers. If you grow dozens or hundreds of acres, you probably don’t have space, overhead resources, or time to hang-dry hundreds of thousands of pounds. Moreover, when you hang-dry, you leave hemp exposed to mother nature’s elements for weeks, increasing the likelihood of contamination. That can be incredibly risky if you live in a humid state like Florida, where mold and mildew contamination is widespread. With the proper hemp drying equipment, you can dry hemp correctly and efficiently, resulting in a product ready for extraction or other industrial or medical purposes.

Our Hemp Drying System is custom-designed and manufactured to improve your individual hemp drying needs. Thorough and fast drying of hemp results in a higher quality product for processing or market. Our Hemp drying systems allow you to dry hemp much faster, resulting in a product ready for further extraction or other industrial or medical purposes.