Chilli peppers can be dried naturally in just the air and sunshine, but it takes several days to finish the chili drying process. Besides the over-long drying period, thicker-skinned chili is not easy to dry in the sun. Would like to dry chili in hours or dry thicker-skinned chili? This heat pump Chili Drying Machine is a wise choice for chili drying if your Chili drying capacity is not very large. It is easy to operate, flexible, highly efficient, and low-cost.

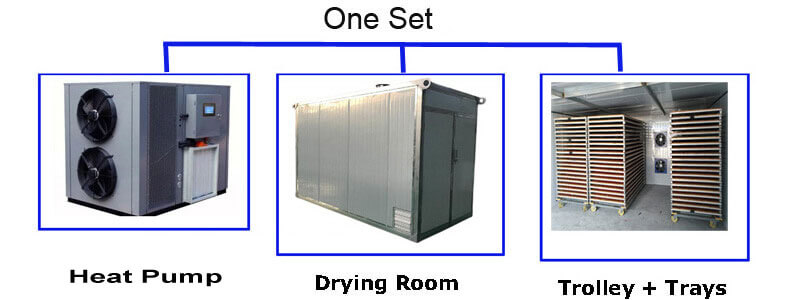

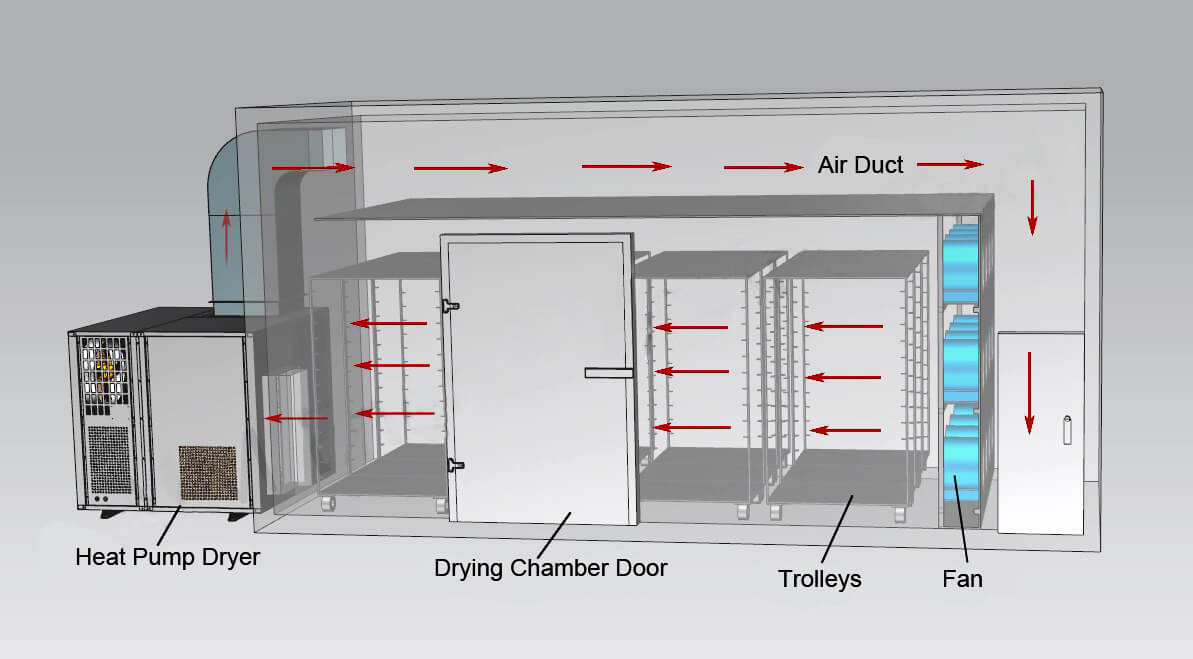

Hot air circulation chili drying machine, also known as heat pump chili drying machine. It is based on the inverse Carnot principle, which gets the energy from the environment air and circulates the heat four times to the drying room to dry materials highly efficiently (maximum air temperature up to 80 ℃).

The heat pump chili drying machine working process.

1. The dry evaporator of the refrigerant absorbs air from the outside.

2. The compressor starts to work to increase the air temperature.

3. The heat exchanger converts the hot air into the drying chamber.

4. The material will be dried by the hot air circulating in the drying chamber.

Heat Pump Chili Drying Machine Features

1. Cycle drying. No pollution

2. Easy installation and operation

3. Good Drying Quality. Keep nutritions

4. Automatic control

5. High Stability

6. Low cost

Parameters of the Heat Pump Chili Drying Machine

I. Dual Circulation Type Food Drying Machines

| Model | WS-7B | WS-14B |

|---|---|---|

| Heat Pump Power (P) | 7 | 14 |

| Drying Chamber Size (L×W×H)(m) |

4.9×2.9×2.15 | 7.1×2.9×2.175 |

| Circulation Air Fans (kw×Qty) |

0.37×12 | 0.55×12 |

| Electric Auxiliary Power (kw) |

20 | 24 |

| Dehumidification Fan (kw) |

0.55 | 1.1 |

| Trolley Qty (sets) | 6 | 10 |

| Trays Qty (pcs) | 192 | 320 |

II. Air Blowing From Below Type Food Drying Machines

| Model | XC-7B | XC-14B | XC-20B | XC-28B |

|---|---|---|---|---|

| Heat Pump Power (P) | 7 | 14 | 20 | 28 |

| Drying Chamber Size (L×W×H)(m) |

5.1×3×2.6 | 6.7×3×2.6 | 8.1×3×2.6 | 10.5×3.2×2.7 |

| Circulation Air Fans (KW×Qty) |

0.75×9 | 1.1×9 | 1.5×9 | 2.2×9 |

| Electric Auxiliary Power (KW) |

20 | 36 | 36 | 36 |

| Dehumidification Fan (KW) |

0.55 | 0.75 | 0.75 | 0.75 |

| Trolley Qty (sets) | 6 | 9 | 12 | 15 |

| Trays Qty (pcs) | 192 | 288 | 384 | 480 |

III. Air Blowing From Top Type Food Drying Machines

| Model | SC-7B | SC-14B |

|---|---|---|

| Heat Pump Power (P) | 7 | 14 |

| Drying Chamber Size (L×W×H)(m) |

4.7×3×2.55 | 6×3×2.55 |

| Circulation Air Fans (KW×Qty) |

0.75×4 | 1.1×4 |

| Electric Auxiliary Power (KW) |

18 | 20 |

| Dehumidification Fan (KW) |

0.75 | 0.75 |

| Trolley Qty (sets) | 6 | 9 |

| Trays Qty (pcs) | 192 | 288 |