I. Introduction of Papayas

1. General information

Papaya is a native to tropical regions of Americas and cultivated originally in Southern Mexico. Nowadays, it is cultivated in most tropical regions of the world. Generally, the papaya fruit is melon-like, oval to nearly round, somewhat pyriform, or elongated club-shaped, and it has a unique and exotic sweet taste.

2. Food value

There are a lot of antioxidants in papaya. Also, vitamin C, vitamin A, and certain minerals are rich in papaya fruit. Papaya also has some substantial minerals such as potassium, magnesium, calcium and so on. The following figures represent the minimum and maximum levels of constituents as reported from Central America and Cuba.

Food Value Per 100 g of Edible Portion of papaya

|

Constituents

|

Fruit

|

|

Calories

|

23.1-25.8

|

|

Moisture

|

85.9-92.6 g

|

|

Protein

|

0.081-0.34 g

|

|

Fat

|

0.05-0.96 g

|

|

Carbohydrates

|

6.17-6.75 g

|

|

Crude Fiber

|

0.5-1.3 g

|

|

Ash

|

0.31-0.66 g

|

|

Calcium

|

12.9-40.8 mg

|

|

Phosphorus

|

5.3-22.0 mg

|

|

Iron

|

0.25-0.78 mg

|

|

Carotene

|

0.005-0.676 mg

|

|

Thiamine

|

0.021-0.036 mg

|

|

Riboflavin

|

0.024-0.058 mg

|

|

Niacin

|

0.227-0.555 mg

|

|

Ascorbic Acid

|

35.5-71.3 mg

|

|

Tryptophan

|

4-5 mg

|

|

Methionine

|

1 mg

|

|

Lysine

|

15-16 mg

|

|

Magnesium

|

_

|

|

Phosphoric Acid

|

_

|

II. Why Dry Papaya

Papaya is the perishable food. Drying is the most common processing technology to preserve papaya by removing most of its water. The lower water content slows the rate of respiration, enzymatic action, and overall deterioration rate makes products less susceptible to decay and much easier and less expensive to store and transport. Papaya is very suitable for drying, and dried papaya retains delicious taste and its nutritive value.

III. Papaya Drying Method

Typically, only the flesh of the papaya is dehydrated. The seeds and skin are discarded by an automatic machine, and the fruit is cut into whatever shape is desired. Usually, cubes or slices are preferred, since they dehydrate faster than halves. Generally, there are some kinds of processing methods for dried papayas, the details of the different processes will be shown as below.

1. Solar Drying

The drying using solar energy has been used since antiquity in order to preserve foods. The simplest method for solar drying is to lay papayas directly upon a flat black surface and allow the sun and wind to dry them.

Solar drying works best in a hot, dry climate. When drying papayas in the sun, place the prepared papayas in the sun for the first 2 or 3 days, then move them to a ventilated shady spot to complete drying. If you live in a location with a high relative humidity, solar drying may take too long to produce a high-quality product.

Advantages: simple drying way, less equipment required and low cost. And also help imperfectly ripened papaya get further maturation.

Disadvantages: Drying process cannot be controlled. Long drying period, higher labor cost and larger drying area, vulnerable to other kinds of environmental contamination and limited by climatic conditions. So natural drying is gradually replaced by manual drying.

2. Conventional hot air drying

|

|

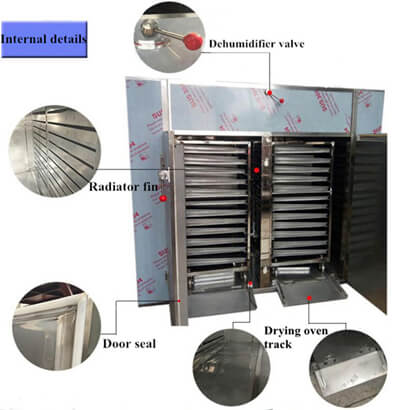

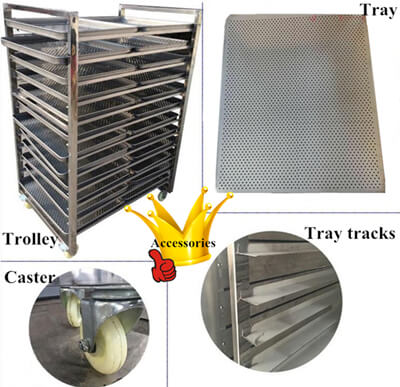

In this type of drying, the heat needed for drying is provided by convection with hot air in direct contact with the papayas. The most common of these dryers used for fruits are hot air drying oven and continuous belt dryer. The hot air drying oven adopts hot air circulation with high temperature resistant axial flow fan and automatic temperature control system. The papaya pieces are put on the trays, then put trays in the trolleys, at last, push trolleys into the drying oven. The continuous belt dryer is formed by an endless belt on which the papayas to be dried is placed and carried through a counter-or co-current flow of hot air.

Advantage: the ease of automatic continuous operation minimizes labor requirement. Less working area with large production capacity, no contamination during drying process, free from environmental impact

Disadvantages: low drying efficiency and long period drying make taste, flavor, and color get worse.

3. Microwave Drying

If you think conventional drying of foods is a slow process, you can attempt to enhance this process which has been made widely in industry. Microwave drying is adopted as efficient drying equipment by more and more consumers in the market. For more information about microwave drying machines, you can visit the “Drying Equipment” of our website.

If you think conventional drying of foods is a slow process, you can attempt to enhance this process which has been made widely in industry. Microwave drying is adopted as efficient drying equipment by more and more consumers in the market. For more information about microwave drying machines, you can visit the “Drying Equipment” of our website.

Advantages: the drying speed is very quick and it can improve the quality of products dramatically. it characterizes high efficiency, even heating, easy to control, and convenient installation and maintenance etc. In addition, microwave automatic temperature vacuum drying equipment still has the functions of sterilization and disinfection. It possesses power linearity adjustable, intelligent control, and environment & temperature controllable. finished papayas are safe and healthy, and their quality guaranteed period can be prolonged.

Disadvantages: due to short drying time error of 1-2mins will result in big difference, resulting in over-drying.

IV. Packaging and storage of dried papayas

Suitable packages for dried papayas include airtight jars, plastic or glass bottles or plastic bags. Fill containers as full as possible to remove air before sealing, and consider heat-sealing or vacuum scaling plastic bags to extend shelf life. Avoid metal containers and keep packaged products in cool, dark place during storage.

Check packages a few days after dried papayas have been scaled inside, if there is any condensation inside the container, then the papayas need further drying. Shelf life is typically one year when products are properly added and sealed in airtight packages.