Shiitake mushroom(Lentinula edodes) is a kind of edible fungus which has high protein, rich dietary fiber, low fat, various amino acid, multiple vitamins, and polysaccharide. It contributes to the human health significantly for its high nutritive and medical value, so it is preferred by many people. Usually, the shiitake mushroom tends to be processed into dried products so that its’ transportation and preservation are easily achieved. Dried shiitake mushrooms are better made by microwave mushroom dryer machine.

I. Why Making Dried Shiitake Mushrooms

I. Why Making Dried Shiitake Mushrooms

1. The fresh shiitake cannot be conserved for a long time, drying is able to restrain the bio-activity of shiitake mushrooms, slow down the metabolism of the shiitake, and also prevent the shiitake mushroom from the harmful microbe, so making dried mushrooms is an effective and important way to prolong shiitake’s shelf life. At the same time, the dried mushrooms are easy to pack and transport.

2. In the cultivation, there will be some low-quality shiitake that is not good enough for marketing, but the fresh shiitake mushroom with poor quality can have an increased value after being made into dried mushrooms.

II. Why Choose Microwave for Making Dried Shiitake Mushrooms

The drying technology has a great impact on the shape, color, and flavor of the shiitake mushroom, so a proper drying method should be applied in making dried shiitake mushrooms.

At present, the shiitake drying techniques include sun drying, hot-air drying, vacuum drying, vacuum freeze drying and microwave drying, etc. Compared to other conventional drying ways, microwave drying is featured by high-quality processing result, high efficiency, energy efficiency and pro-environment.

|

|

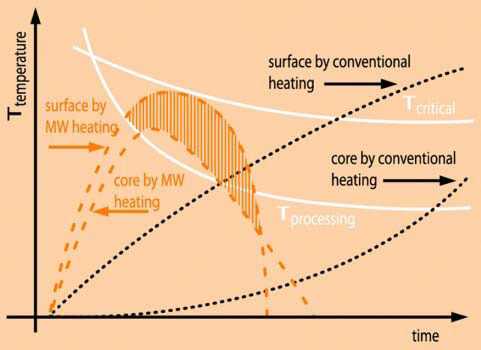

1. Shorter drying time

The outstanding advantage of making dried mushrooms is speed. Instead of utilizing energy only to the outside of products, microwave drying by microwave dryer machine works directly to dry materials from the inside to the outside. It can dry materials in less of the time required by conventional methods. Moreover, short drying time is helpful to keep the original quality of the product, because the color, flavor, and nutrition of the product are mostly reserved.

2. Even drying

Microwave drying makes the product interior and exterior absorb the microwave at the same time to reach an even drying result. So productive efficiency is significantly improved and energy consumption is significantly reduced.

3. Qualified product

Microwave systems have superior controls to make product temperature much easier to regulate, which contributes to higher quality. By the way, there is an extended of microwave drying, which is microwave sterilizing.

III. Microwave Drying Widely Used for Making Dried Shiitak

1. How to dry shiitake mushroom by microwave

The microwave drying technology has been used widely in processing shiitake mushrooms. Let’s see how to dry shiitake by microwave mushroom dryer machine.

Microwave drying works to realize dehydrating by the principle of the product generating heat effect to evaporate the water content after absorbing the microwave. The electrical energy is transformed into microwave via the magnetron, and then the microwave radiation acts on the shiitake mushrooms. The temperature of the shiitake mushroom increases and its moisture content is changed into steam and removed from the drying chamber.

2. Multiple utilization of microwave mushroom dryer machine

Our microwave mushroom dryer machine has multiple uses

♦ For drying and sterilizing various edible fungus and other foods;

—Cereal products: bread, noodles, tofu, etc.

—Vegetables: carrots, cabbages, peas, potatoes, etc.

—Fruits: apple slices, banana slices, lemon slices, kiwi slices and other fruit slices.

♦ For medicines, medicine materials drying and sterilization;

♦ For dehydrating powdery, granular, sliced and striped materials, etc.

We are dedicated to manufacturing microwave equipment for industrial use. With advanced high-frequency heating methods, our microwave drying machines assure clean operation and avoid creation of dust, smell, noise, and vibrations. The professional equipment can produce high quality dried products, without pollution in the environment and no effect on the human health. If you are in the drying business of food, chemical products, medicine, etc. drying and sterilizing, we are ready to offer professional information and high-quality drying machines for your specific demands!