The Continuous Mesh Belt Leaf Drying Machine uses clean hot air as a drying medium, it is the ideal drying equipment for drying herbaceous plants. it can process spices and herbs such as curry leaf, bay leaf, spicy wood leaf, herbal basil leaf, fenugreek leaf, neem leaf, mint leaf etc. The working temperature is controllable, It will effectively preserve the property, quality and color of raw materials. Fast, industrial-scale solution to leaves drying.

The Components of Continuous Mesh Belt Leaf Drying Machine

- Leaves Feeding conveyor (Fresh leaves enters the dryer through the conveyor for drying)

- Discharge conveyor (Used to transport dried leaves)

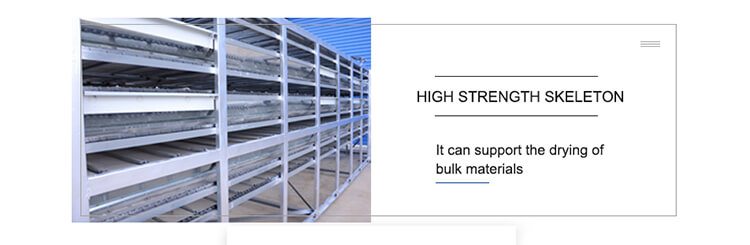

- Drying host ( the material loading into drying host mesh belt and move forward from top layer to bottom layer)

- Fan (Provide sufficient air volume to the dryer to improve the drying efficiency.)

- Heat exchange furnace ( providing heat for drying machine,the cold air and hot air make exchange, then enter into the dryer absorb by fan)

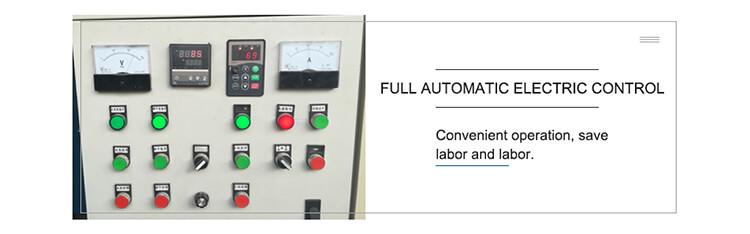

- Control panel (control the leaves dring speed and temperature.)

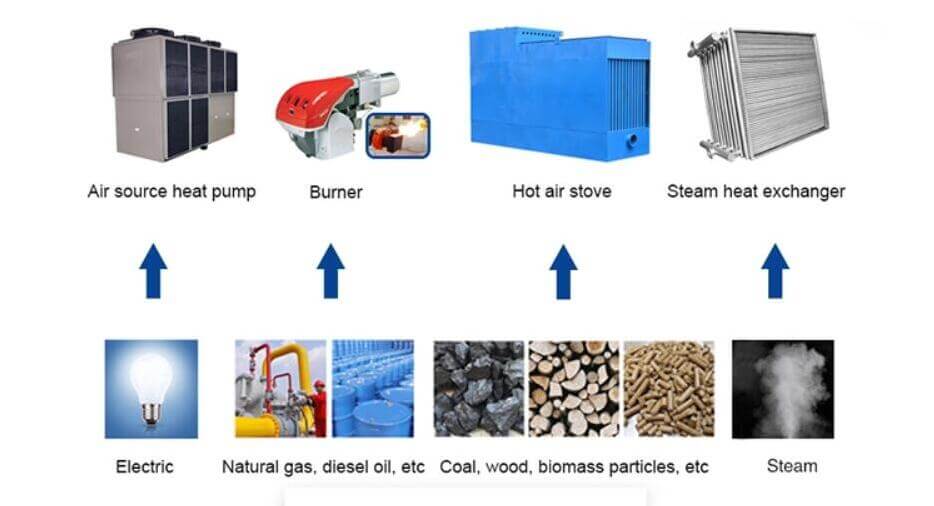

- Fuel: Wood,electricity,biomass,gas,diesel,propane,steam.

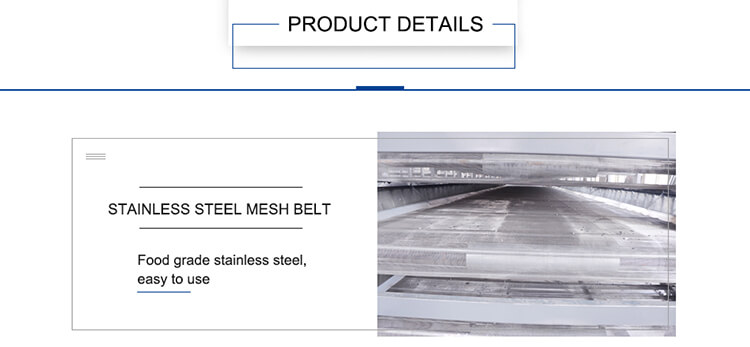

Materials are conveyed by multilayer stainless steel mesh belts. The hot air passing through the mesh belt from the bottom layer to the top layer, the final moisture is discharged from the top of the dryer and the dried product is discharged through the discharge conveyor belt.

The Continuous Mesh Belt Leaf Drying Machine Advantage

1. The drying medium is pure hot airautomatic circulation, will not contaminate the raw material.

2. Continuous mesh belt movement ensures even and consistent dehydration.

3. With medium and low temperature drying mode, the dried material has good color, small deformation and little loss of nutrients.

4. Electronic controls allow operators to dial-in optimum air volume, belt speed, and temperature.

5. Each layer of mesh belt is equipped with a material stop and guide plate to prevent materials from falling directly from the upper layer to the next layer.

6. Convenient door handles allow panel access to view the status of the drying operation.

7. A wide range of heat sources, electricity, gas, diesel, wood and biomass.

Why are our Continuous mesh belt leaves drying machine so popular?

1.Advanced heat source system

Environment friendly and energy saving, no pollution in the drying process.

2.High energy air supply technology

The Belt leaves dryer utilizes a heat recapture system which recycles up to 80% of the system heat for maximum efficiency and operating cost savings. Uniform calorific value exchange, high production efficiency.

3.Advanced dual-drive technology

Stable perfermence, high degree of automation, labor saving.

4.Strong compatibility

It can process a variety of similar shapes of materials such as moringa leaf, bay leaf, lotus leaf, etc.

5 Fast, industrial-scale solution to leaves drying.

All material touchpoints of the Mesh Belt Dryer are made from 304 stainless to meet food-grade standards.