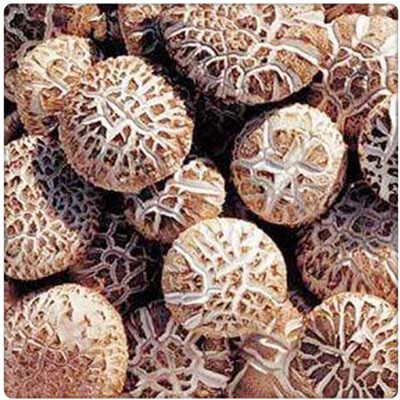

Introduction to Honeysuckle Flower

Benefits of Honeysuckle Flowers

Benefits of Honeysuckle Flowers

Jin Yin Hua is an anti-bacterial and anti-inflammatory herb used in Traditional Chinese Medicine for clearing heat and relieving toxicity from the human body.

Honeysuckle is an antibiotic effective against bacteria including staphylococcus aureus, streptococcus pneumoniae, salmonella typhi, pseudomonas aeruginosa, mycobacterium tuberculosis, bacillus dysenteriae, vibrio cholera, diplococcus pneumoniae, diplococcus meningitidis.

Honeysuckle flowers are traditionally used in Chinese medicine to treat fever, abscesses or swellings in the body, boils, sores, inflammation affecting the breasts and urinary tract, sore throat, as well as dysentery.

Why Drying Honeysuckles by Microwave Dryer Machine

Traditional drying methods of honeysuckle flowers are natural drying or drying in the drying room. Natural drying is restricted by the weather. During rainy days, the buds will not be dried timely, which causes great losses. Honeysuckle flowers dried in the sunny days lose some color. Drying in the drying room has low efficiency, and the quality of dried flower is difficult to control.

Microwave drying machine uses the microwave to dry the honeysuckles. Microwave penetrates through the flowers to produce friction heat, making the temperature of the flowers rise, the moisture contained is evaporated, achieving the aim of drying. The inside and outside are heated simultaneously, fast drying speed, uniform drying effect, the drying quality is good. Besides, the machine also has sterilization effect.

Introduction to Honeysuckle Microwave Drying Machine

Microwave drying machine can achieve the de-enzyme and drying of honeysuckle flowers. The machine utilizes the moisture in the flowers to form the steam environment, achieving good de-enzyme effect combining with the vibration of the high-frequency microwave. The de-enzyme honeysuckle flower is bright in color and some moisture is lost, saving the cost of the drying process. After the de-enzyme process, the flowers are processed again by the microwave equipment to finish the drying process. The dried flowers have a uniform drying effect and verdant color, the nutritional components are not destroyed or changed, meanwhile, the herb dehydrator also has sterilization function.

Microwave Herb Dryer Machine Features

1. Adopt non-contact infrared temperature measurement technology, multi-point temperature measurement, having high precision.

2. Human-machine interface operation, PLC touch screen automation control, high work efficiency, saving labor.

3. Continuously adjustable microwave power for adjusting the drying intensity, frequency adjustable conveyor speed for changing the drying time.

4. Temperature and humidity interlocking control, ensuring the color and quality of the dried flower.

5. Microwave leakage≤1mW/cm2, ensuring safe operation.

6. The machine can be customized according to your special requirements.

7. The machine is also suitable for the de-enzyme and drying of rose, chrysanthemum, peony, lavender, tea, etc.

Influencing Factors on the Honeysuckle Drying Quality by Microwave Drying Machine

By adjusting the microwave power, the drying intensity can be changed. With the increasing of microwave power, the drying time is reduced, the dried quality is worse. Microwave power should be set accordingly.

By adjusting the microwave power, the drying intensity can be changed. With the increasing of microwave power, the drying time is reduced, the dried quality is worse. Microwave power should be set accordingly.

● Honeysuckle Drying Quality and Heating Time

By adjusting the conveyor speed, the drying time of honeysuckle can be changed. Under certain microwave power, with the increasing of heating time, the color of honeysuckle will change more severely. Users should reduce the drying time while achieving the aim of drying, which can improve the quality of dried flowers as well as improve drying efficiency.

● Honeysuckle Drying Quality and Layer Thickness

Under certain microwave power, the thicker the honeysuckle layer, the moisture produced by drying is more difficult to be discharged, which covers the surface of the flower, causing its color change.