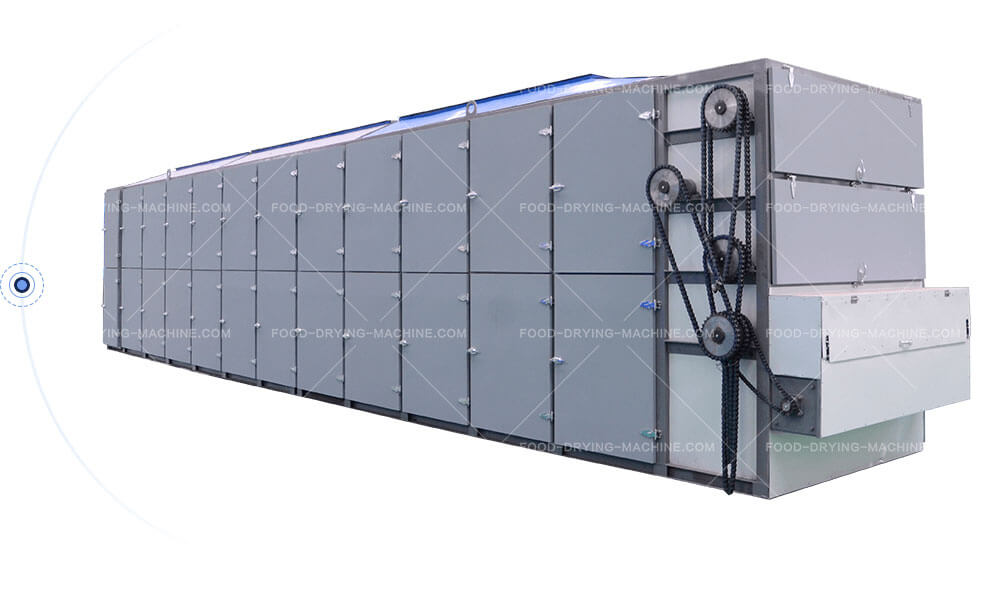

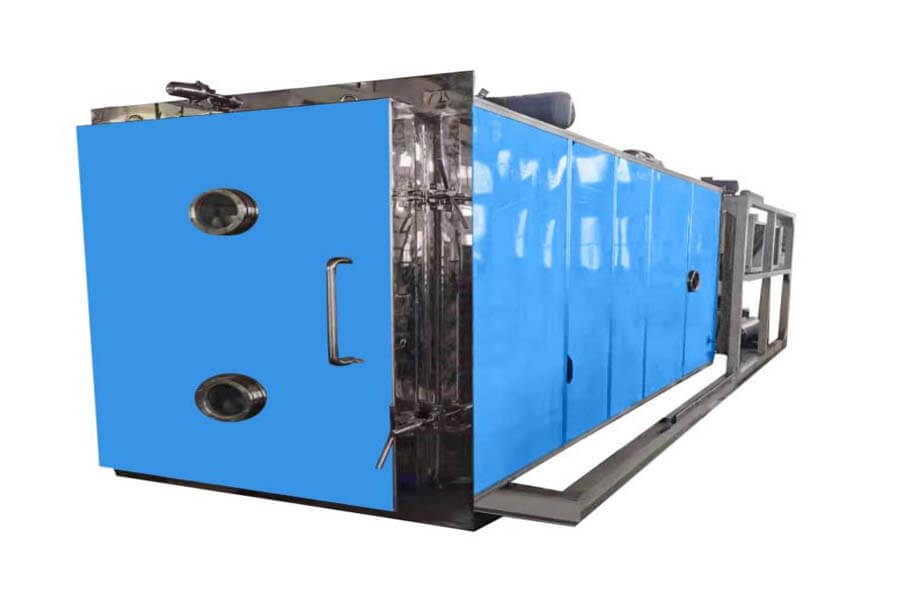

Hot Air Circulation Food Drying Oven Introduction

The hot air circulation food dryer machines are particularly designed to uniformly dry material in quantity at a setting temperature and have little influence on food flavor, texture, and color. It takes advantage of circulated hot air in the oven to get materials dried, which brings high efficiency and saves energy. As one of the general drying equipment, the series food drying machines are equipped with a high temperature resistant axial flow fan and automatic temperature control system. Our hot air drying oven is a versatile drying equipment widely employed in the food industry, the pharmaceutical industry, the chemical industry, and other industries. We offer drying machines with different capacities like single-door hot air drying ovens, double-door hot air ovens, and large-scale drying ovens to meet customers’ specific demands.

Features of Hot Air Circulation Food Drying Oven

- Most of the hot air is circulated in the drying oven. The thermal efficiency of the drying oven can reach about 70%.

- Low noise, reliable and safe operation, temperature-controlled, easy installation and maintenance.

- Equipped with adjustable air divider plates inside the oven, materials can be dried evenly.

- The drying tray is made of stainless steel, easy to move, durable, and convenient to clean.

- The heat source can be chosen from steam and electricity. The electricity heating way is recommended due to more convenient and secure than the steam.

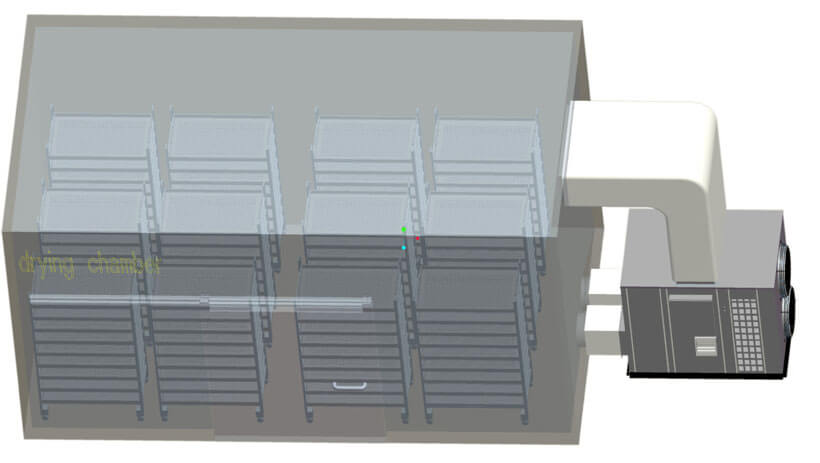

Structure of Hot Air Food Drying Machine

This hot air food drying oven, also called an electrothermal blowing dry box, is composed of angle iron, stainless steel plates, and heater. The hot air circulating system is composed of a cyclone separator, air blower, air filter, and heater. It uses steam or electricity to heat air which then dries materials circularly.

Main Parts of Hot Air Circulation Dryer Machine

1. Baking plates:

♦Punched plate: modest permeability, suitable for particulate materials

♦ Manual multi-square plate: good permeability, suitable for bar & slice materials and loose materials

♦ Nonporous Plate: bad permeability, suitable for powder and liquid materials

2. Axial flow fan: low noise and high-temperature resistance. The fan can be customized.

3. Baking vehicle: baking vehicles and their wheels are made of carbon steel or stainless steel. Their customization is also available.

4. The radiator is the auxiliary part of the hot air drying oven, and the customization of the radiator is available.

Working Principle of The Food Dryer Machine

The food drying machine is heated by a heater through steam or electricity and a lot of hot air is circulated in the oven. The biggest characteristic of this hot air drying machine is that the hot air circulates inside the oven and the whole circulating process is closed, thus enhancing heat transfer and energy saving. When the hot air reaches the top of the chamber it is circulated back to the bottom by a fan installed inside the chamber and hence the optimum amount of heat is achieved gradually inside the hot air oven. Fresh air from the inlet supplement, waste heat discharged from the exhaust vent, constantly added fresh air and continuously discharging hot and humid air. As a result, a hot air circulating oven can maintain appropriate humidity and reduce the temperature difference inside the cabinet. Thus, the materials’ drying process might be in a good state.

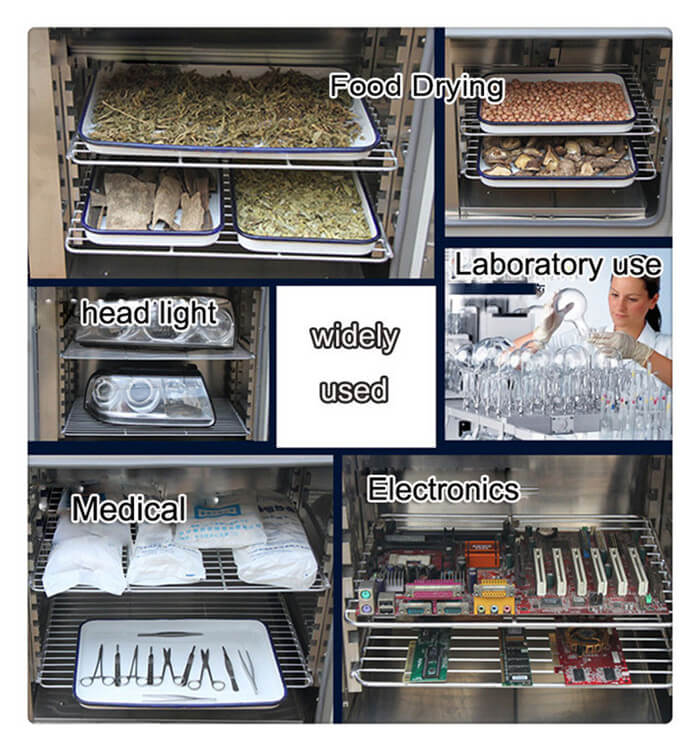

Multiple Applications Of Hot Air Food Drying Oven

1. The hot air circulating oven is suitable for pharmaceutical, chemical, foodstuff, and light industries. It can be used in heating and drying raw materials, Chinese traditional medicines, powders, granules, vegetables, etc.

2. The air circulation oven is also adapted for curing ink and drying paint film. It is widely used in the precise drying of electron components, electroplated products, plastics, metals, PC boards, glass, building materials, etc.

Technical Data of Hot Air Circulating Drying Oven

| Model |

CT-C-0

|

CT-C-I

|

CT-C-II

|

CT-C-Ⅲ

|

CT-C-IV

|

|

Capacity of each batch

|

60kg

|

120kg

|

240kg

|

360kg

|

480kg

|

|

Power of Fan

|

0.45kw

|

0.45kw

|

0.9kw

|

1.35kw

|

1.8kw

|

|

Consumption of steam

|

5kg/h

|

18kg/h

|

36kg/h

|

54kg/h

|

72kg/h

|

|

Total Power

|

9kw/h

|

15kw/h

|

30kw/h

|

45kw/h

|

60kw/h

|

|

Thermal area

|

5m2

|

20m2

|

40m2

|

80m2

|

100m2

|

|

Air volume

Temperature used

|

3450m3/h

±2°C

|

3450m3/h

±2°C

|

6900m3/h

±2°C

|

10350m3/h

±2°C

|

13800m3/h

±2°C

|

|

Quantity of trays

|

24

|

48

|

96

|

144

|

192

|

|

Overall Dimension(mm)

|

1460*1000*1750

|

2300*1200*2300

|

2300*2200*2300

|

2300*3220*2000

|

4460*2200*2290

|

|

Baking vehicles

|

1

|

2

|

4

|

6

|

8

|