Food Freeze Dryer Introduction

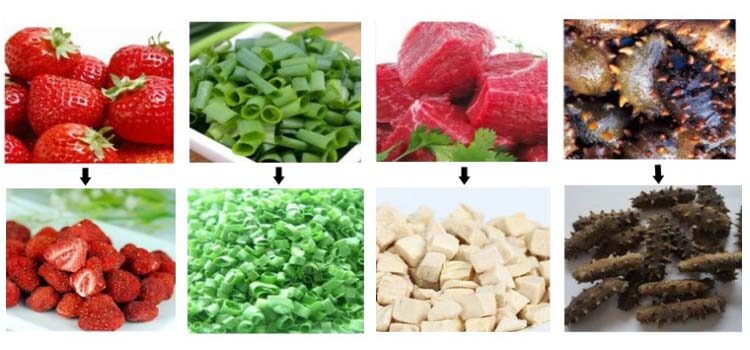

Freeze drying is a whole new way to preserve food. The freeze-dried food is porous and crisp and can last 25 years or more, better than dehydrating, canning or freezing. It can be restored to its own shape by adding water, and its color, aroma, shape and activity are basically unchanged. Best of all, freeze-drying preserves all of the color and flavor as well as 97% of the nutrition of fresh food, so freeze-dried food is high profit and winning an increasing market.

Our food freeze dryer is designed to dry almost all popular products at a reasonable price. It quickly freezes the liquid in the material into solid ice, vaporizes the ice directly, and removes the gas continuously, so as to achieve the purpose of drying the material. In this freeze-drying process, freeze-dried food maintains its original size and shape with a minimum of cell rupture. Customize Freeze Dryer is available to meet your requirement.

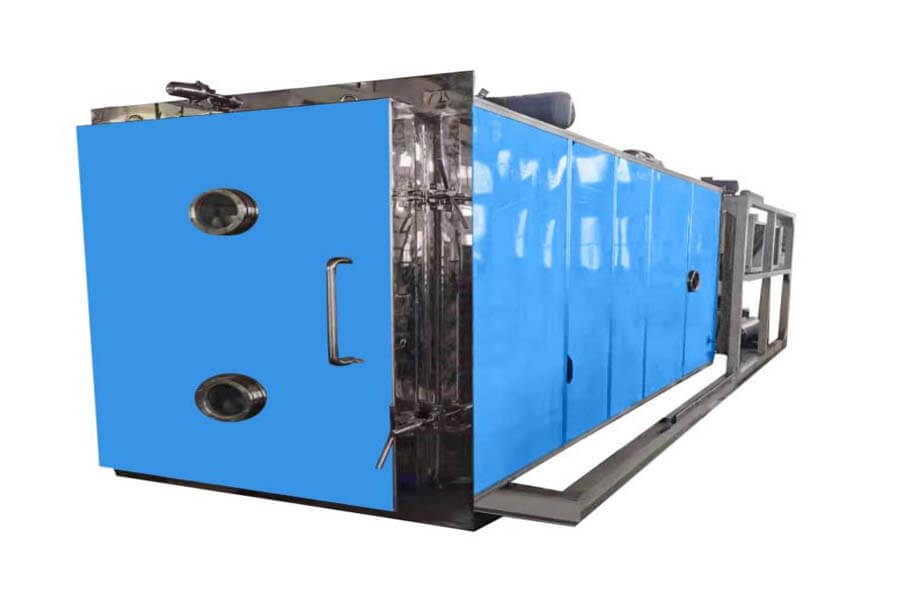

TDDG-10 Food Freeze Dryer

The food freeze dryer is mainly include drying chamber, refrigeration system, vacuum system, heat exchange circulate system, ice condencer, automatic control system, pneumatic system, cleaning and disinfection system. All the units group are in the same rack.

Input capacity:100kg/batch

Material: stainless steel 304

Power: 27kw,3-phase,380V,50HZ

Weight: 6000kg

Overall dimension: 4800*1800*2200mm

Tank body shape: Default square shape. Round shape: customizable

Ice catching ability: 100kg/batch

Trays quantity: 28 pcs

Trays size: 650*550*30mm

Quick-freezing design temperature: -30 – -40℃

Max drying temperature: +80℃

Control program: Independent programming, with remote control function

Freeze Dryer Feature

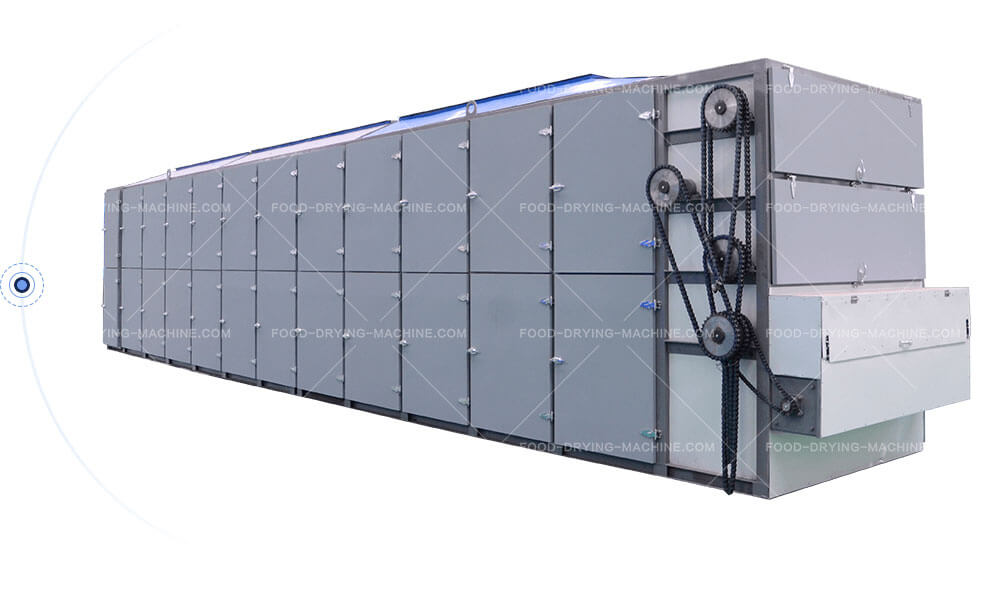

1, The tank shell and the units group are in the same rack. After the whole is transported to the site, it can be used as soon as the water and electricity is connected, which is convenient and quick;

2, No need to equip a quick-freezer room or quick-freezer machine, the raw materials will automatically undergo quick-freezing and drying processes after entering the tank.

3, One-key automatic operation, and discharge from the tank after the freeze-drying is completed.

4, Automatic and manual switching freely.

5, The system has permission settings to prevent misoperation. Various fault alarm display. The system can be remotely controlled after authorization.

6, User-friendly and easy-to-understand operation interface, with display of the working status of each component, temperature and vacuum. More functions can be added according to user needs

7, Multiple freeze-drying data and curves can be set saved copied and printed.

8, The freeze-drying formula curve can be adjusted at any time during the freeze-drying process.

9, Any parts of the freeze dryer can be customzied to meet your needs. The power supply, tray size, size of machine, SIP/CIP functions, and even brands of our components(compressor and vacuum system) can be customized. One year warranty, free online service.

Freeze Dryer Application

1, High Value-added Fruit and vegetable drying industries.

2, Aquatic products and meat: shellfish, shrimp, fish sticks, beef, pork, chicken, mutton and so on.

3, Seasoning products: garlic powder, ginger powder, onion powder, tomatoes, pepper.

4, Healthy products and instant drinks industries.

5, Pharmaceutical and biotechnology industries. Freeze drying is now a standard process used to stabilise, store or increase the shelf life of drug products and other biologicals

6, Vaccines and antibodies. penicillin, blood plasma, proteins, enzymes, hormones, viruses and bacteria

Food Freeze Drying Process

Food Freeze drying is based on the process Lyophilization. Lyophilization or cryodesiccation is a low-temperature dehydration process that involves freezing the product, lowering pressure, then removing the ice by sublimation.

1 Pre-freezing

Materical is frozen at temperature much below the freezing point of water, i.e. -20°C to -30°C

2 Vaccum

It is done to reduce the pressure inside the drying chamber

3 Primary Drying

Temperature is increased in primary drying, as the pressure is already low so this causes the sublimation of frozen water(ice) to vapour. This vapour reaches the condenser, where it condenses back to frozen ice and then easily removed from the outlet.

4 Secondary drying

Gradual temperature rise (up to 50°C) extracts almost all remaining “bound” moisture from the product.