Multi-layer Continuous Belt Food Drying Machine Introduction

Multi-layer Belt food drying machine is a continuous convective drying processor in which the drying of the product takes place on ventilated conveyor belts. The food drying machine is widely applied for mass production of continuous drying for sheet, and strip pellet material with better ventilation properties, especially for materials that cannot bear high temperatures such as dehydrated vegetables, and herbal pieces of high moisture content. Our Multi-layer Belt System is custom-designed and manufactured to improve your individual drying needs.

Distinctive Features of Continuous Belt Food Drying Machine

1. Special multi-layer belt design can make the materials heated uniformly and continuously which highly improves the drying efficiency.

2. The time of material staying on the belt and velocity of feeding material can be adjusted in order to obtain the best drying effect.

3. Hot air can be circularly applied, and the energy is greatly saved.

4. Large capacity, high drying, and thermal efficiency.

5. Low energy consumption, easy to operate and maintain.

6. Wide utilization range, many kinds of materials can be dried such as fruit and vegetable drying, flower and herb drying, grain drying, industrial drying, and more.

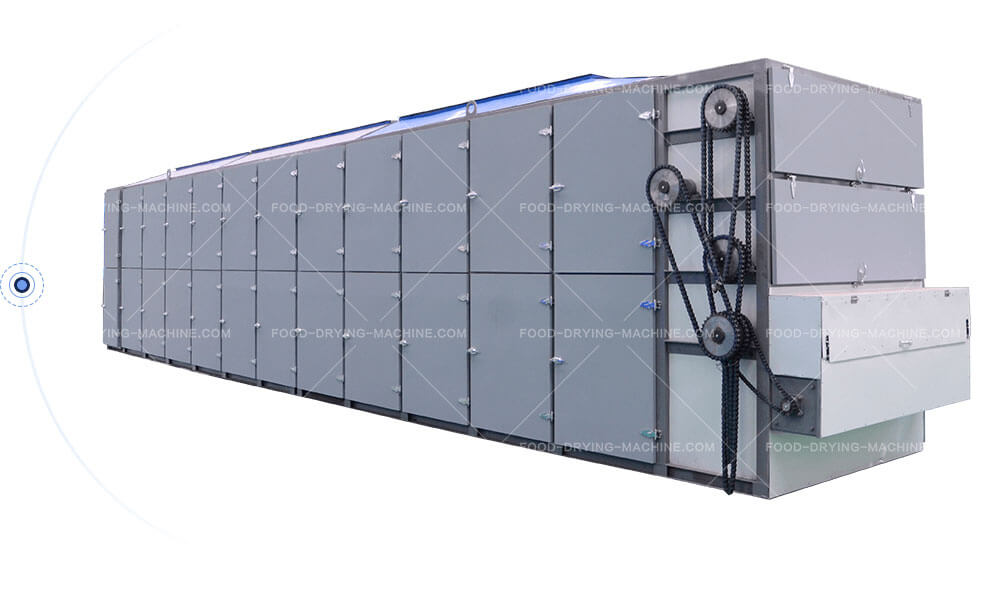

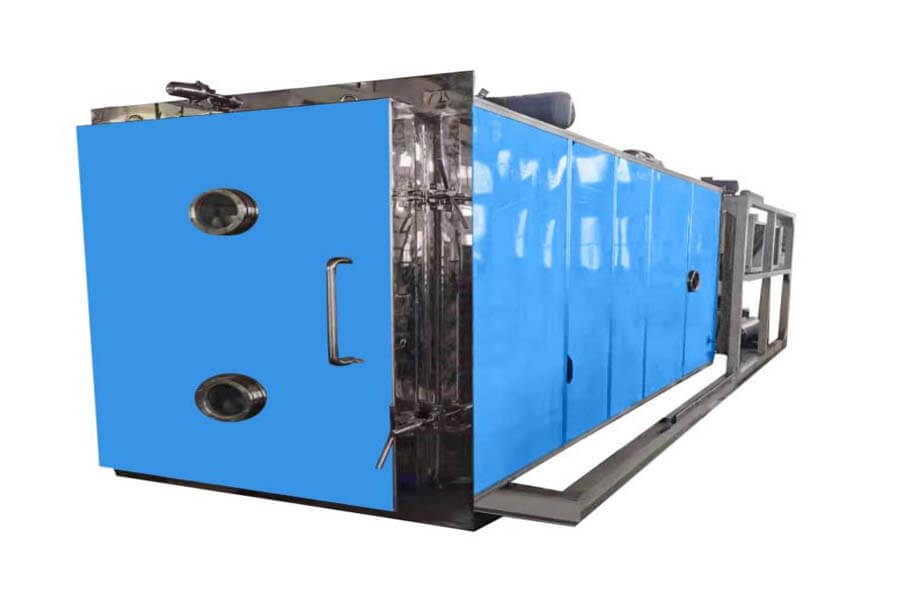

Main Structure of Multi-layer Continuous Belt Food Drying Machine

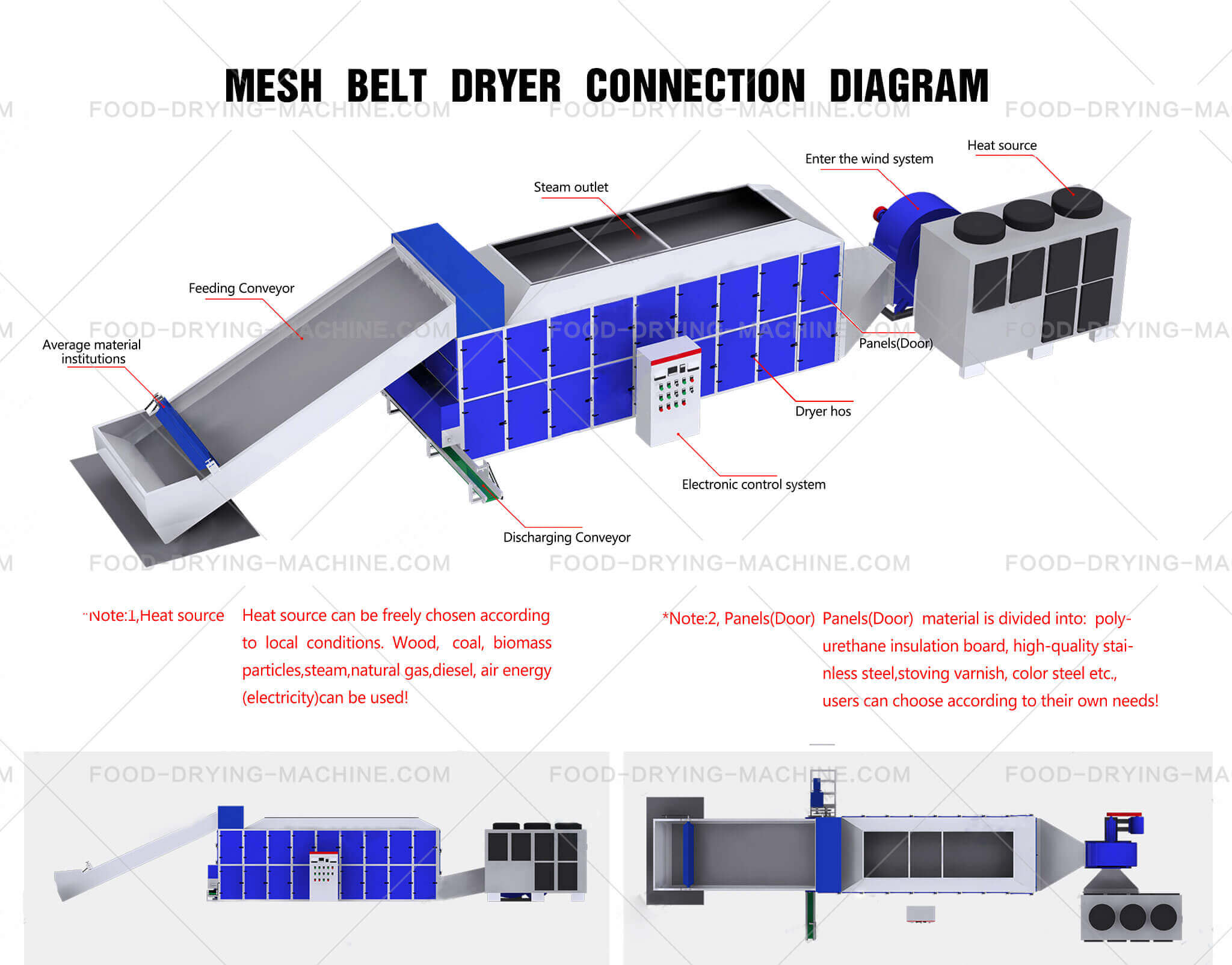

This continuous belt drying machine includes the following main parts: a drying room, feeder, heat exchanger, circulating fan, circulation blower, control valve, belts, and some other accessories.

Working Principles of Multi-layer Belt Food Dryer

This Continuous Belt Dryer is designed to utilize the combination of heat and air to rapidly dry materials. Material enters via the conveyor into a multi-layer belt system whereby it is dried by airflow and heat. As the material moves from one belt to the next, the plant material drops off and mixes around for a more even dry.

After the wet material is evenly fed onto the top layer of the drying belt via the belt conveyor feeding system, the moving drying belt transports the wet material to the other end and drops beneath the layer of the drying belt. The beneath drying belt then transports the wet material and moves in the opposite direction until dropping onto the third layer of the drying belt. At the same time, hot air is evenly blown into the dryer via the bottom air distributor. With the help of exhaust fans, the hot air penetrates the wet material on each layer of the drying belt for heat transfer and takes away the evaporated moisture. When the material reaches the bottom drying belt, it is dried for discharging.

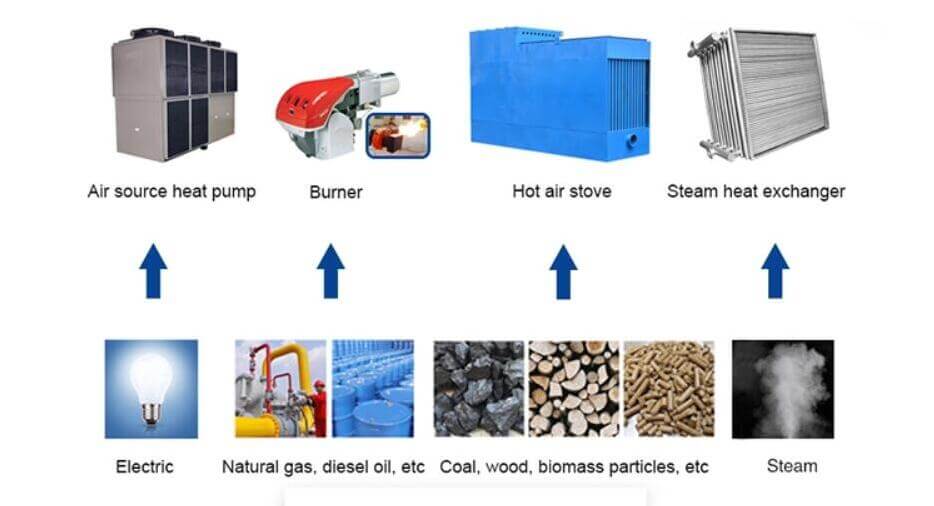

Multiple Heating Source Selection

You can Choose Heating Source According to Your Local Energy Advantages

Technical Parameters of Continuous Belt Food Drying Machine

| Model | DW1.5-6-4 | DW2-8-4 | DW2-9-4 | DW2-10-4 | DW2-12-4 | |

| Layers | 4 | 4 | 4 | 4 | 4 | |

| Drying area(㎡) | 29 | 45 | 51 | 57 | 69 | |

| Spread thickness of material(mm) |

50-200 |

|||||

| Working temperature(℃) |

0-120 | |||||

| Drying time (hour) |

0.1-5 |

|||||

| Capacity(t/h) | 100-150kg/h | 200kg/h | 250kg/h | 300kg/h | 400kg/h | |

| Heat exchange furnace(M) |

3.2*1*2.7 | 3.9*1.26*3 | 3.9*1.26*3 | 4.7*1.5*3 | 4.7*1.5*3 | |

| Induced draft fan (kw) |

11 | 15 | 15 | 22 | 22 | |

| Exhaust fan (kw) |

1.5 | 1.5 | 2.2 | 2.2 | 2.2 | |

| Feeding Conveyor(kw) |

1.5 | 2.2 | 2.2 | 2.2 | 3 | |

| Discharge Conveyor(kw) |

0.55 |

|||||

| Total power(kw) | 14.55 | 19.25 | 19.95 | 26.95 | 27.75 | |

| LP gas consumption

(90 ℃ Fahrenheit) |

20m³/H | 25m³/H | 28m³/H | 30m³/H | 36m³/h | |

| Place requirement

(W*L*H)M |

4.5*14*2.7 | 5*19*2.8 | 4.5*20*2.8 | 5.5*21*2.8 | 5.5*23*2.8 | |